Don’t feel like reading? Click above to listen to this article!

Do your friends still joke that you go to work simply to watch paint dry? If so, this article may be what you’ve been waiting for (literally). You wouldn’t be “watching paint dry” if the products you use could be applied wet on wet. Let’s explore some myths and concerns surrounding the alleged witchcraft behind applying additional coats of paint before the previous coat has dried.

#1 – “If it worked, people would have been doing it centuries ago.” You’re right; they have. The technique dates back to Baroque times, and even has a nickname, “alla prima” (“first attempt” in Italian). Although it was first used in oil painting, it has developed into a popular technique for concrete sealers, paper coatings, and linseed oil coatings.

#2 – “If it worked, everyone would be doing it.” Right again. It’s especially true in the auto industry. They apply multiple wet coats, and the clear topcoat is generally always applied wet on wet. The obvious advantages are reductions in energy costs (due to fewer bake cycles) and a 20% reduction in production time. Using similar principles, the auto industry claims to have pioneered the “wet bed” technique, which involves spraying a reducer or clear base coat prior to the primer application to help with surface wetting and edge blending. A not-so-obvious benefit of this process is said to be superior gloss. And don’t forget about fewer heaters and other equipment to control ambient conditions.

#3 – “That’s great for the auto industry, but I work in bridge (or oil & gas).” Hold your ponies; you’re probably already applying wet on wet. If you stripe coat edges, welds, bolts/nuts, and rivets (on older structures) as the specification often says to, and then apply a full coat once the stripe coat is tacky, you’re applying wet on wet (known as wet striping). In addition to improved coverage, wet striping produces a tacky surface and the subsequent full coat application theoretically adheres better.

#4 – “The risks outweigh the benefits.” How’s this for a benefit? Imagine the potential for increased adhesion between coats with the availability of reactive bonding sites present in an uncured coating film. It would be long-awaited vengeance on the dreaded amine blush. Various patented polymer technologies use unreacted surface components to their benefit inside and outside of wet on wet applications. Certain two-component materials including urethanes can be heated in order to un-cap polyols or other previously non-reactive sites, and are often followed with a coat of epoxy. Now there’s a role reversal. So throw away your sandpaper, and forget about inter-coat contamination. That’s nothing to shake a paint stick at.

#4 – “The risks outweigh the benefits.” How’s this for a benefit? Imagine the potential for increased adhesion between coats with the availability of reactive bonding sites present in an uncured coating film. It would be long-awaited vengeance on the dreaded amine blush. Various patented polymer technologies use unreacted surface components to their benefit inside and outside of wet on wet applications. Certain two-component materials including urethanes can be heated in order to un-cap polyols or other previously non-reactive sites, and are often followed with a coat of epoxy. Now there’s a role reversal. So throw away your sandpaper, and forget about inter-coat contamination. That’s nothing to shake a paint stick at.

#5 – “Speeding up application could adversely affect performance of the coating system years from now.” Maybe not. A paint manufacturer or a coatings testing laboratory can evaluate comparative coating system performance by applying coating systems wet on wet and under normal inter-coat drying times, then subject the coating systems to accelerated corrosion resistance, accelerated weathering, thermal cycling, perhaps a variety of physical tests depending on the intended service environment, and even evaluate barrier properties using Electrochemical Impedance Spectroscopy (EIS) to determine whether performance of the coating systems are affected by wet on wet verses wet-on-dry application.

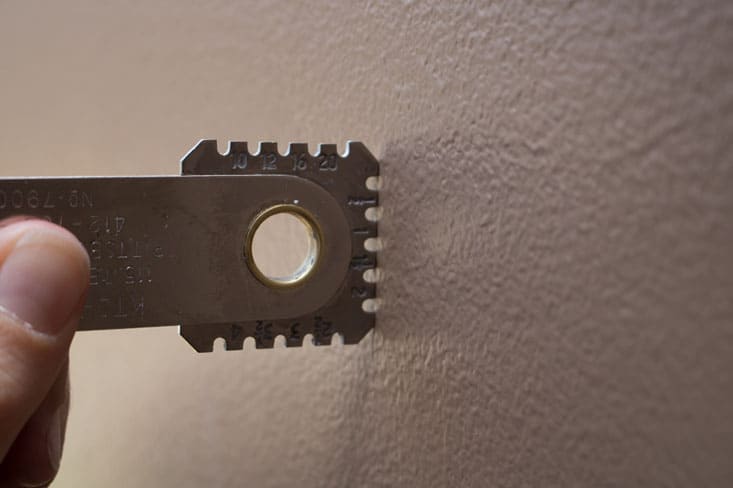

#6 – “But I want to measure the dry film thickness of each coating layer.” That presents a problem. All coating thickness gages require contact with the coated surface, so underlying coats must be dry before they can be measured. So if you want wet on wet, you’ll have to rely on wet film thickness measurements or the total system thickness once it has dried. You can’t have it all!

There aren’t a large number of products on the market that claim to possess the wet on-wet application feature. Historically, the only industrial applications of wet on wet coating application have involved 100% solids products. However, there are an increasing number of products that weigh in at 50-65% volume solids. Here are a few generic references to wet on wet applications in the industrial market.

In a recent disruptive development, one manufacturer announced the release of its proprietary process which allows their products to be applied wet on wet. At 65% volume solids, it is a step in a new direction from the customary 100% solids products. Initially developed for use on offshore oil & gas assets, the application process minimizes the potential for intercoat contamination and includes the added benefit of carbon nanotechnology, leading to its integration in many industrial market sectors.

Another manufacturer produces a high-solids epoxy primer that is formulated specifically for wet on wet application. It is typically paired with a urethane topcoat, and is primarily used on industrial equipment, building materials and agriculture equipment. Yet another manufacturer produces a one-component primer system that allows the topcoat to be applied wet on wet and is used for industrial applications. Finally, high ratio calcium sulfonate alkyds (HRCSA) are used for overcoating lead-based paint on bridges and a variety of other structures. They are applied by a wet on wet process that involves a penetrant, then caulking of joints and spot priming, followed by overcoating. In fact, they remain soft and impart minimal stress on the underlying aged coating system.

In conclusion, don’t count your chickens and rule out an application technique just because it sounds too good to be true. Could watching paint dry ever become a thing of the past? Since only a limited number of products available at this time, it’s unlikely that it will be anytime soon… but the possibility exists.

About the Author:

Carly McGee is the Materials & Physical Testing Laboratory Supervisor for KTA where she has been employed for 15 years.

Carly McGee is the Materials & Physical Testing Laboratory Supervisor for KTA where she has been employed for 15 years.

Excellent article, Carly! I’ve worked for more than 20 years with paint and I’ve never seen problems in applying stripe coat and just after aplly the whole coat and of course it was wet over wet and results were very good.

Congratulations

1. Why apply wet on wet; to double the thickness? Then why not apply double the thickness at the first instance, what is going to happen probably sagging and long time requirement for drying of doubly thick coating. If at all feasibility could be there manufacturers shall have to research to find product by product the exact state of wetness of the first coat over which the second coat can successfully cured. Thereafter also long time will be required to achieve proven performance as well as proven track record.

The concept is academic but let’s hope the technology may come true some day.

The article rightly points there is nothing great expectation that wet to wet concept will be a tenable technology. Why wet to wet to double the thickness? What would have happened if initially the coating was applied at double the thickness, probably snagging or dipping on vertical surface. What is the surety that the second coat wet to wet will be compatible, will from a single consistent film. If manufacturers or academician want to standardize such wet to wet application technology enormous research will be required to find out the exact state of 1st wet coat over which second wet coat will be compatible and cure. Then again question of proven system and proven track record will come up.

But nothing is impossible may be some day or other standard wet to wet technology will come up and will be used to the much time saving and comfort if the contractor and asset owner.

WET to WET by default.

How many paint inspectors follow the stepwise applications of specified coating systems? Doubtful case, most of them would be roaming about and come back to site at their comforts. We had a specification for maintenance painting of offshore platform: St3 + 1 Coat of Surface tolerant epoxy followed by 2 coats of High Build Polyamide cured Epoxy. I was visiting the platform for some other assignment. When I reached the site, the painting crew completed St3 and Surface Tolerant Epoxy as per spec. and applied 1 coat of H B Polyamide Cured Epoxy, there after waiting,with the spraying machines and other tools and tackles, for the coated surface to become tack free or tacky. How long they will wait if there is no stringent inspection and supervision and by Default the application might be Wet to Wet.

Interesting article, Carly. A bit contentious at the industrial and marine end of the coating spectrum? …Having dipped into the superyacht coating industry for a while, I saw in practice some of the advantages you mention for wet-on-wet application. And also one downside mentioned: harder to control thickness because DFT isn’t measured coat by coat. It’s probably harder to avoid sagging and holidays, for example. Another possible downside: increased potential for trapped non-reactive diluent (eg. solvents), unless the coating is truly solvent-free (or applied in very thin coats (eg. automotive and superyacht topcoat)). …Still, perhaps there is mileage here, in respect of wet-on-wet discussions and development in the marine and industrial sectors, despite their relatively fast and furious airless coating methods. Thanks for the post. Jonathan Scotland

For measuring the thickness of various coats, a good method is to affix a test panel near the production surface so that it receives the same coverage of all coats. Then after drying and baking, the test panel coating can be sectioned, polished and viewed under the microscope. The resulting photomicrographs can often show not only the thickness of each coating but also the profile of each coat, indicating if thin areas or orange peel is creating thin or thick spots. Once again, a picture can be worth more than words.

FT,

If total DFT measurements are not adequate, this is a good idea if you have access to the right equipment to do it. If not, the same concept could be followed with the thickness measured using a Tooke Gage.

Thanks for your comment.

very good article Carley,

I need stainless steel WFT guage how can get

Hello Nikeesh,

You can find it over at KTAGage.com

https://ktagage.com/product/kta-tator-wet-film-thickness-gauge/

OR

https://ktagage.com/product/kta-aluminum-wet-film-thickness-gauges/